Lab Secrets………..or how we make our chocolate

Once we receive the sacks of beans, BeanCraft’s work begins to try and do justice to the fantastic quality beans we are so lucky to work with. For BeanCraft the magical process of turning those beans into chocolate takes place behind an anonymous looking door in the BeanCraft Chocolate Lab!

Lab is a good name for it, as the chocolate making process is much like a science experiment where the chocolate “scientist” tries their best to understand and master every aspect of the process and its variables to produce the best chocolate they can. For us this experimentation is always fun, sometimes frustrating and tiring, but always rewarding. Like in life in general, we have made, and will undoubtedly make more mistakes (nobody mention Garyth….or getting that roast wrong……) but as we learn we improve, and can certainly taste the difference from the first experimental bars we tried on our friends and family (thanks to all for sacrificing your taste buds!).

Below is insight into how we make our chocolate, including some of our Lab Secrets…..

The first stage in the BeanCraft Chocolate Lab is to hand sort the beans. This is an important stage to remove any beans which show evidence of being damaged during fermentation or processing, beans which have not formed correctly in the pod or where beans have become stuck together during the drying process.

After sorting, the next step is to roast the beans. For each new batch and origin of bean we develop a unique roasting profile which aims to find the literal sweet spot for each bean! To find this sweet spot we roast a test batch of beans against a standard temperature profile, and then take a small sample of beans every minute from 20 to 30 minutes. When cooled we taste these samples to find the time at which the flavour profile is at its best. These timings can vary significantly between bean origins. Once we are happy with the results we can start roasting full batches. The smell of roasting beans is incredible!

From the oven the beans are spread on a stainless steel table and cooled. As they cool they crackle and sing as the thin skins begin to separate from the nib inside. We then leave the beans to rest overnight…..

The next day we crack the beans by passing them through serrated rollers which leaves us with a mix of thin papery shell and broken up nibs.

The process to separate the nibs from the papery shell is known as winnowing. For this we use our home made winnowing machine which, using an attached vacuum cleaner draws the lighter skins to one side of the machine whilst allowing the heavier nibs to fall through and be collected. The shell does not go to waste though! It can be infused to make a delicious light cacao tea, or used as mulch in the garden.

After winnowing, the nibs are sorted once more to remove any last bits of shell, as this can adversely effect the flavour of the chocolate.

The next, and longest stage is grinding and conching. Before the main grind we pre-grind the nibs to make them easier on our grinders. We then slowly add the nibs into the grinder where the action of the granite wheels against the granite base, and warming from friction, slowly breaks down the nibs into a smooth liquid. After a few hours we add the other ingredients needed for the recipe. We then watch, smell and most importantly taste the chocolate throughout the grind period.

Depending on the recipe and the bean origin, the total continuous grind time can be from as little as 24 hours up to 72 hours. The chocolate is ready when the taste, smell and mouth feel are just right! This can be a very tricky balance to drive off volatile acids to the right level, at the same time as having the correct mouth feel.

To make sure we are consistent we also check the particle size using a grindometer. We aim for an average particle size of around 25 microns to get the mouth feel we love.

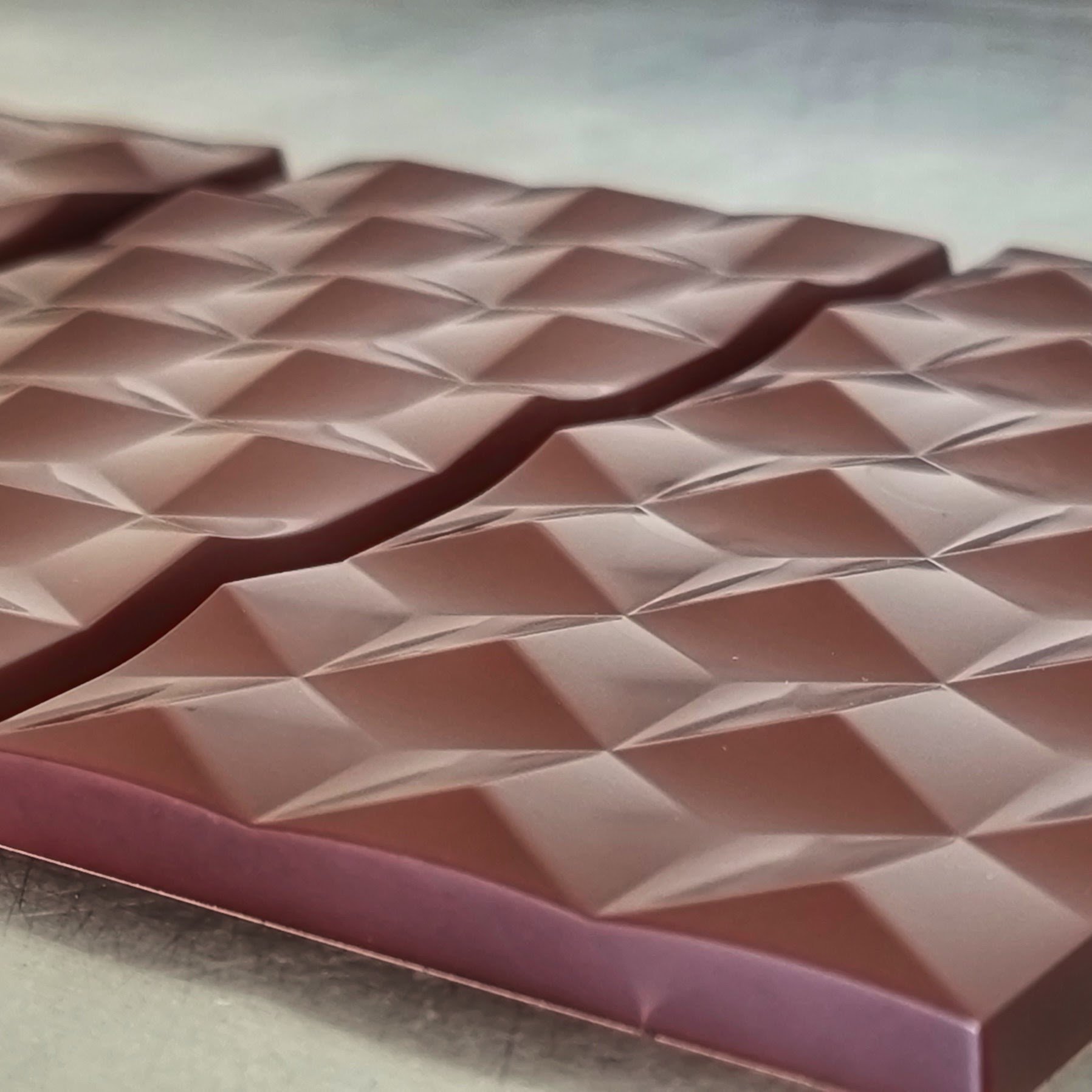

After grinding the chocolate is poured into blocks. It then rests and matures for around a month, during which the flavours continue to evolve and balance. Once matured the chocolate is ready for the final phase of production, tempering and molding. Tempering is the secret which changes the chocolate from a crumbly consistency to having that characteristic snap. During the tempering process, the chocolate is melted to the point where the crystal structure is destroyed and then very precisely cooled, to create the ideal type 5 crystals within the chocolate which give the perfect snap, and glossy finish to the bars.

Once tempered, the chocolate is molded into bars and packaged.

All the packaging we utilise for our products, and for delivery is recyclable. Our bars are first packed into a food safe glassine envelope. Glassine envelopes are ECO Friendly and made from pure pine wood cellulose which is 100% recyclable, biodegradable, compostable and environmentally friendly. The bars are then wrapped in recyclable craft paper.

For deliveries we utilise minimal recyclable cardboard packaging with minimal plastic content. If additional protection is required we use cardboard or paper, or we re-use packaging which we have received.

We hope this gives you a small insight into the bean to bar process we use to make our chocolate (including a few of our Lab Secrets!), and the time and love it takes to produce a bar that does justice to the growers of the beans. We hope you agree its worth it!